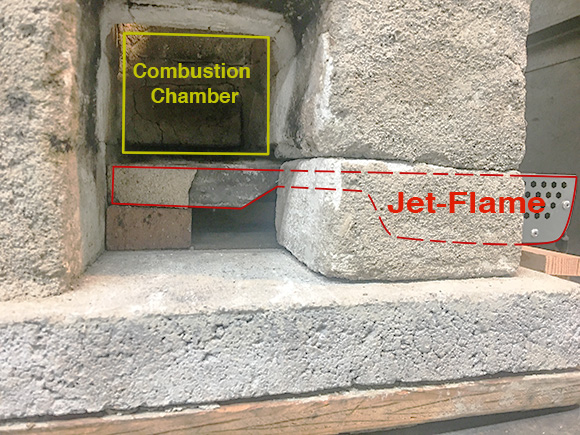

Varying Fan Speed in the SSM Jet-Flame/CQC Stove

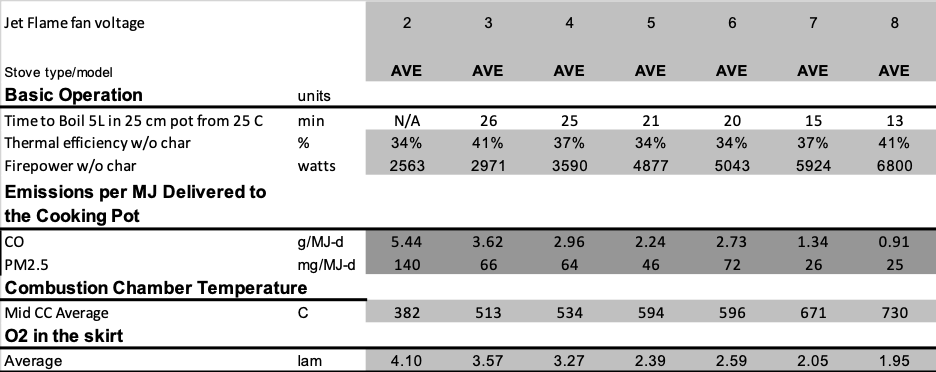

ARC is investigating how to optimize the performance of the SSM Jet-Flame in the CQC earthen brick stove. Forty six thirty-minute ISO 19867 Water Heating Tests were completed under the LEMS hood at seven fan speeds. Two 4 cm x 4 cm douglas fir sticks were burned side by side. Five liters of water in a seven liter pot were heated, and the CQC pot skirt was used in all tests.

Results

Tier 4 ISO Voluntary Performance Targets:

- Thermal Efficiency 40% to 49%

- CO <4.4g/MJd

- PM2.5 <62mg/MJd

Time to boil: The time to boil decreased with an increase in fan speed.

Thermal efficiency: The thermal efficiency stayed close to 35% in most cases and was higher at 3 and 8 volts (around 40%).

Firepower: The firepower rose to 6.8kW at 8 volts, starting at 2.6 kW at 2 volts.

Emissions of Carbon monoxide: Generally emissions decreased with increasing fan speed.

Emissions of PM2.5: 7 and 8 volts scored the best, at half of the result of 5 volts.

Combustion chamber temperatures: The mid combustion chamber temperatures rose with increases in fan speed from 382C to 730C.

Excess air: Lambda fell as voltage increased from 4.1 to 1.9.

We recommend that the project do enough field testing to determine what settings are preferable to local cooks, remembering that higher voltages consume more power. In this way, the Jet-Flame/CQC stove can be tailored to regional cooking, keeping in mind the power output and use patterns of the CQC photovoltaic solar system.

Here’s what the flame looks like when varying the voltage:

Aprovecho Research Center

Aprovecho Research Center