Charcoal Stoves: Ups and Downs!

Ken Newcombe and C-Quest Capital have seen firsthand how charcoal production has wiped out forests in Africa. Making charcoal is a very energy inefficient process (Aprovecho Institute, 1984a). Burning off the volatile compounds in wood consumes and wastes between 50% and 80% of the energy! Ken recently observed that saving charcoal was not easy, and that field tests indicated that traditional stoves were as fuel efficient as more modern stoves. So I asked Ken if he had read Sam’s paper* on how to save fuel in charcoal stoves, and Sam sent it to him.

Busy people are out in the world accomplishing things. There’s a ton of information on the Internet and lots of it is conflicting. Publishing information in journals and books sometimes seems to be a fairly ineffective way to reach actively engaged stovers. That’s why we publish this weekly newsletter, trying to disseminate data driven information. Maybe you can pass it to on to your colleagues?

After testing many charcoal stoves, Sam concluded that:

“Using the minimum load to complete the WBT [water boiling test] results in similar performance between most charcoal stoves, while filling the combustion chamber with fuel results in large differences on the same measures. Based on these laboratory results, limiting the size of the combustion chamber so as to prevent excess fuel loading may be an effective technique for decreasing fuel consumption while cooking.” *

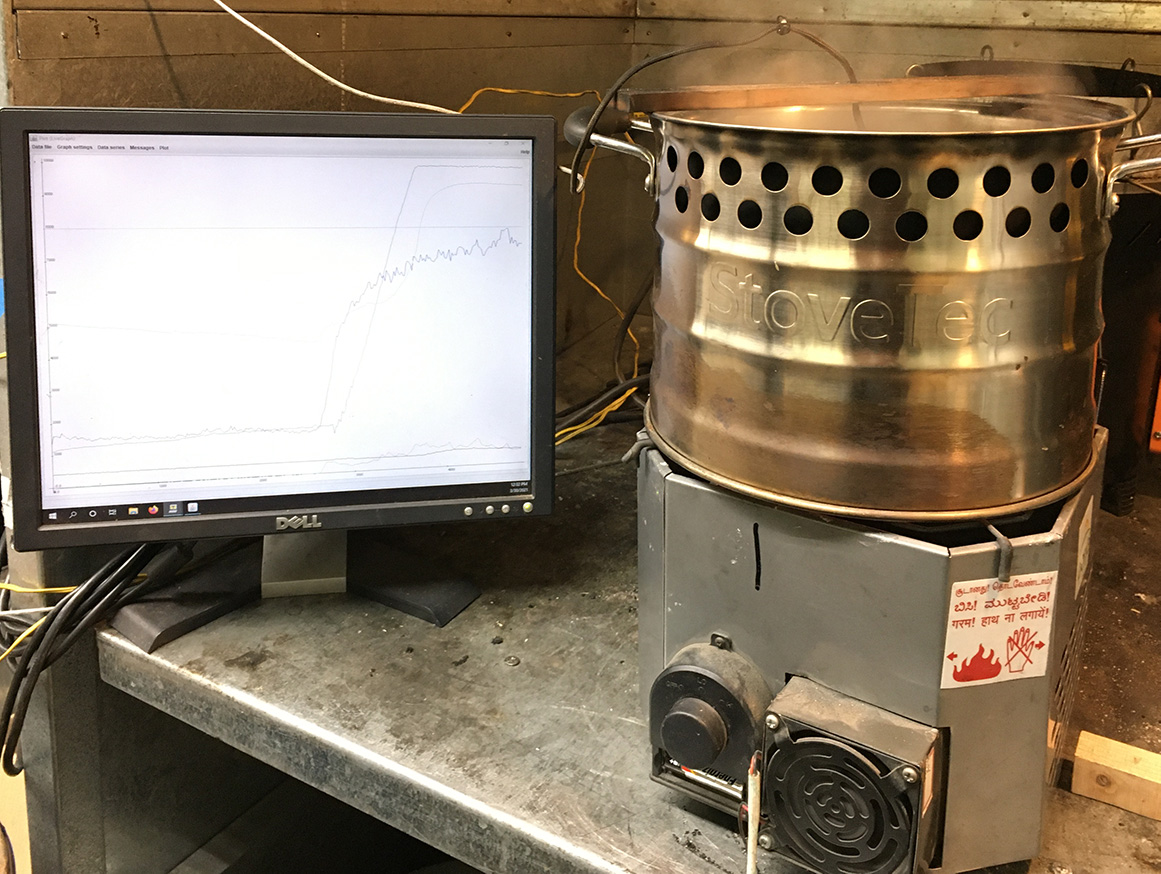

The loaded charcoal is used up, so loading only the amount needed for the cooking process is very important for saving fuel. At the same time, Sam and Ryan Thompson spent a year exploring charcoal burning and came up with an “all Tier 4” charcoal stove that was higher scoring than the other optimized wood burning stoves that ARC made for the US DOE.

CAD drawings and a chapter on charcoal describe what Sam and Ryan did and how to build the stove they invented. (Clean Burning Biomass Cookstoves, 2021, www.aprovecho.org/publications-3).

*(Energy for Sustainable Development, 2013, Bentson, Still, Thompson, Grabow)

Lance MacCarty

Lance MacCarty