Shipping and Climate Change

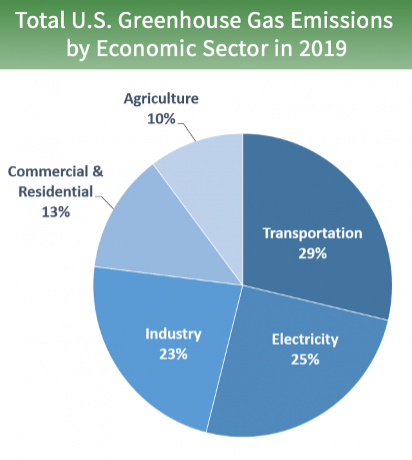

I recently read a Time article that pointed out that shipping accounts for 2.2% of annual global greenhouse gas emissions. To put it in perspective the writer, Aryn Baker, suggests that if shipping was a country, it would be the sixth largest CO2 emitter in the world, on par with Germany.

In her reporting from last year’s COP26 (UN Climate Change Conference), she writes:

“It doesn’t matter if we want iPhones that come from China, steaks from Brazil or to tow an iceberg to Glasgow; we all depend fundamentally on international shipping for everything that we do,” says Johannah Christensen, head of the Global Maritime Forum.

“This just underscores the importance of decarbonizing shipping.”

Some ferryboats have transitioned to battery power. For the 60,000 ocean going cargo ships transporting global goods, the most promising technology, says Christensen, is either hydrogen or synthetic fuels.

Making these fuels available sustains the globalization the world depends on for just about everything. In The Age of Aquarius, renewable fuels keep ships rolling on the high seas as we transition from grey to green. Check it out!