Secondary Air Jets in Charcoal Stoves?

Charcoal stoves are batch loaded like TLUDs (top loaded up draft stoves), but they differ greatly in how air flow is used to encourage combustion. A charcoal stove has lots of primary air blowing up into the fuel. A TLUD uses a small amount of primary air to create a relatively constant amount of woodgas that is then combusted by a mixture of secondary air and flame above the fuel bed. The large amount of primary air in a charcoal stove tends to create the fire underneath the fuel, while the secondary air jets in a TLUD concentrate the fire above the batch of fuel.

If a TLUD allowed as much primary air as a charcoal stove into the bottom of the fuel bed, too much wood gas would be made and the TLUD would be smoky. I wonder if charcoal stoves could be patterned after TLUDs? Could a charcoal stove be top lit with jets of secondary air and flame on top of the batch of fuel? Would such an arrangement result in better performance? Would added secondary air in a charcoal stove maintain the fire on top of the fuel that would burn up the woodgas (predominantly CO in a charcoal stove)? Might this increase heat transfer efficiency since the temperatures (convection and radiation) might be hotter?

When Sam Bentson and Ryan Thompson studied how to improve charcoal stoves in the DOE 2011 project, they found that adding pre-heated natural draft jets of air did help to create more flame where it’s needed, right under the pot. Unfortunately, they also experienced that charcoal makes less flame than wood and covering the entire top of the fuel bed with flame (as in a TLUD) is difficult. Forced draft secondary air might be more successful, especially since charcoal stoves are usually short and do not generate needed velocities. To be most effective, the jets of air/fire should meet in the middle of the combustion chamber and cover the entire fuel bed. It seems to be best to use the minimum velocity necessary since too much air only cools the fire (Udeson, D.J., 2019, University of Washington).

We’ll try it and report on the results.

Charcoal Stove Design Principles (Ryan Thompson)

- Size the combustion chamber for the required task. Whatever fuel is loaded into the stove will be burned at a rate proportional to the amount of air made available to it. In most cases, more fuel means higher firepower because there is always excess air. For small amounts of food/water, where not much power is required, either load a small amount of fuel into the stove, or use a stove with a small combustion chamber. For cooking lots of food at once, use a stove with a big combustion chamber.

- Charcoal stoves can have a high turn-down ratio. If the primary air supplied to a charcoal fire is reduced close to zero, the fuel will still keep burning. When the air supply is increased, the firepower will also increase. Normally there is a spike in CO when the air supply is increased sharply, but it tends to stabilize once the firepower comes back up.

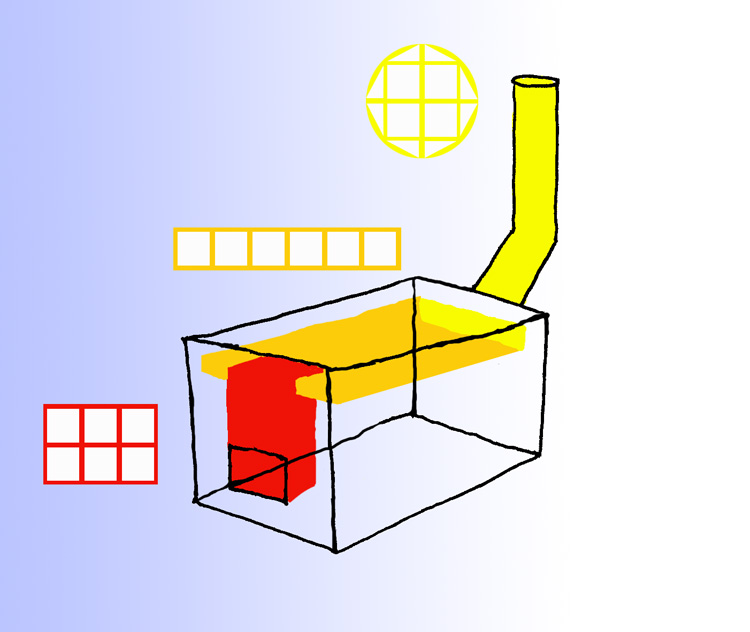

- Use pre-heated secondary air jets to burn up the CO. Most charcoal stove designs have air coming in from the bottom and sides of the fuel bowl. The air must pass through the burning charcoal before it gets to the top of the fuel where the CO is being emitted. If hot air is added above the charcoal, it is available to combust the CO. Try to keep the bottom of the batch of charcoal as cold as possible and burn down from the top of the batch of the fuel.

- Position the pot close to the charcoal. This maximizes heat transfer from radiation.

- Insulate the stove body. Insulate the stove body until a temperature of 620˚C or higher is achieved above the burning fuel. Insulation needs to be lightweight and trap still air. Examples of good insulation are: ceramic fiber, rock wool, wood ash, sheets of foil, etc.

- Use small channel gaps between the pot and the stove. The pot can be located very close to the top of the burning charcoal. A skirt with a 6mm channel gap around the pot helps increase the heat transfer efficiency from convection. Both convective and radiative heat transfer are important in a charcoal stove.

- Maintain a constant cross sectional area throughout the stove to start the design process and reduce as directed by experimentation under the emissions hood. This will help to keep the velocity of the draft as high as possible.

- Supply a large amount of primary air to assure sufficient firepower. Make the primary air door large enough to boil the water quickly. The door can be partially closed to reduce power when desired. The door has to be almost airtight to reduce firepower sufficiently when simmering in a pot with a lid.