Post Combustion Reduction of PM2.5

Both automobiles and the biomass industry rely on improving combustion efficiency and post combustion reduction of PM2.5 to achieve “clean burning.” It’s really hard to rely on the combustion chamber to burn up enough of the harmful smoke to protect health, especially in large scale applications. Of course, all efforts should be made to be as efficient as possible. The goal is to burn up everything! In cookstoves, with limited space and a pressing need to be affordable, the problem becomes more acute.

Biomass heating stoves are larger and can cost a lot more than cookstoves. Industrial technologies are even less constrained. For decades, home heaters have tried catalysts to reduce emissions. Factories have used a wider array of technologies including filtration, catalysts, and electrostatic precipitation. Chapter 8 in “Clean Burning Biomass Cookstoves, 2nd edition, 2021” includes explanations of these technologies.

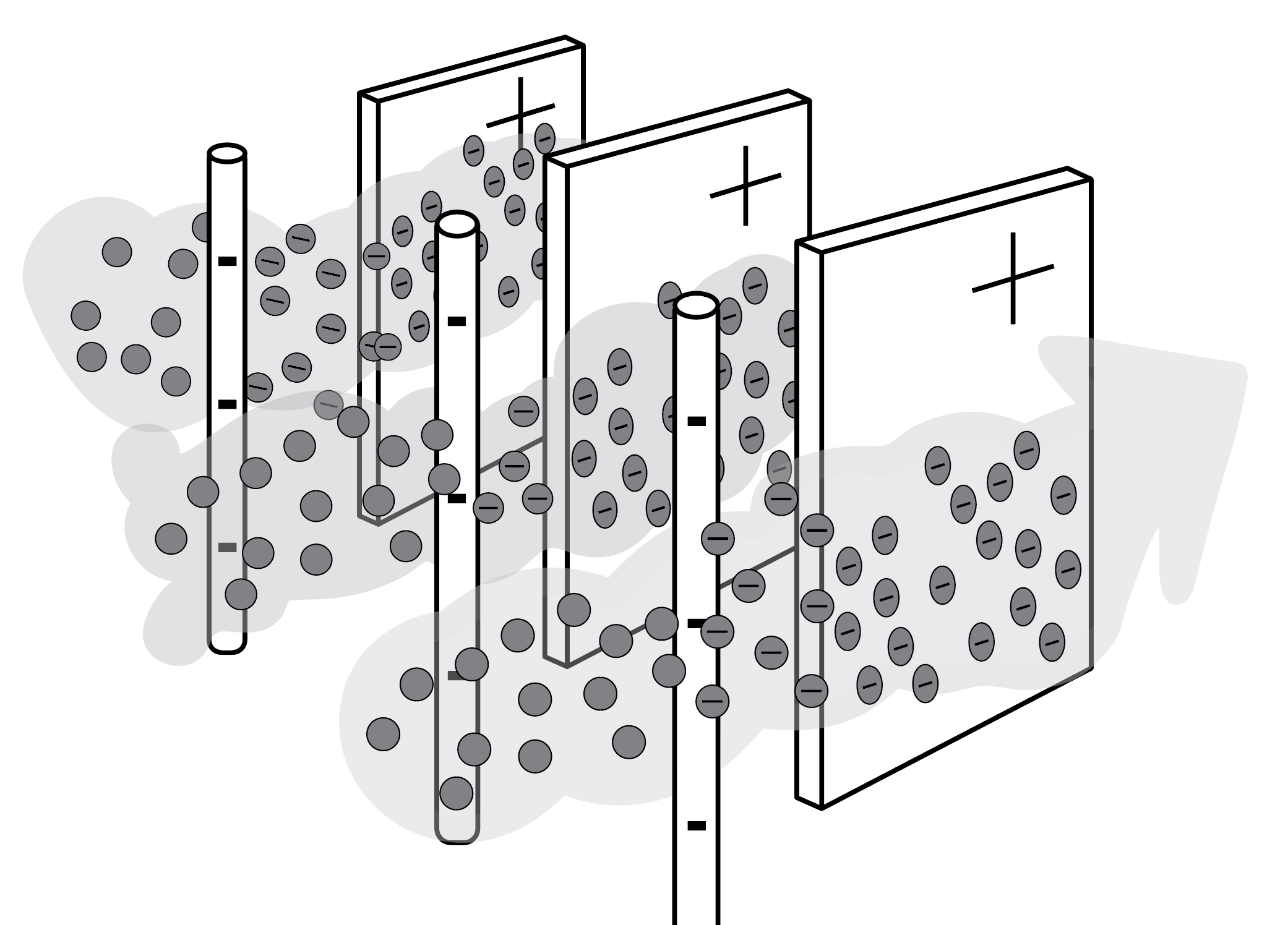

Generally, filtration can work very well to capture dust and smoke with reported efficiencies of up to 99% (Frisky, et al., 2001). Catalytic converters are placed into the hot exhaust path where temperatures are hot enough (above 426°C). They work well with CO (30% to 95%) but not so well to remove PM2.5 (30% to 40%) (Hukkanen, et al., 2012). The Swiss electrostatic precipitator (ESP) called the OekoTube has been measured to reduce PM2.5 by 80.2% to 97.7% (Brunner, et al., 2018). However, as in industrial uses, routine cleaning is necessary to remove creosote and other coatings that interfere with proper function. Unlike filters and catalytic converters, the low wattage ESP does not reduce the draft in the stove, which could be potentially advantageous.

ARC has been experimenting with post combustion of PM2.5 since 2017 as a result of the EPA SBIR funded work to create a clean burning biomass heating stove. We believe that if ESP is to be useful, automatic self-cleaning must be included, as in some industrial products. The hope is to invent super clean combustion but it’s great that post combustion approaches already exist. On the other hand, forced draft mixing, which is relied upon for combustion efficiency in industry, is largely missing in both cookstoves and residential biomass heaters. Perhaps its addition will be sufficient to reach the goals of protecting health and carbon neutral fuel use with renewably harvested biomass?