A Clean Open Fire?

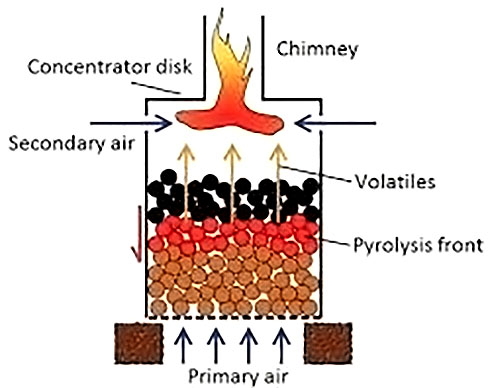

Illustration from: Birzer et al. (2013) “An analysis of combustion from a top-lit up-draft (TLUD) cookstove”, Journal of Humanitarian Engineering 2(1):1-8 DOI:10.36479/jhe.v2i1.11

When Dr. Tom Reed and Dr. Larry Winiarski added short, narrow chimneys above the fire in TLUDs and Rocket stoves, they increased draft and created laminar flow flame in the tubes that could bring higher temperature gases to the pot, increasing thermal efficiency. It also made it harder to add mixing to the stoves since the column of flame in the short chimney resisted injection of air.

Laminar flow relies on molecular diffusion, leading to poor and slow mixing of fuel and air. Combustion efficiency can be lower because incomplete mixing may leave unburned fuel resulting in higher emissions when compared to turbulent conditions. Laminar flame is a smooth ordered flow with reactants moving in parallel layers. The flame front is relatively stable as in a candle.

Turbulent flow, on the other hand, is chaotic with fluctuating eddies that mix fuel and air together. The combustion is characterized by wrinkled, chaotic, and often shorter flames. The improved mixing results in more fuel coming into contact with the air and usually higher combustion efficiency. Turbulent flow can be jumpy and irregular with vortices. Mixing creates an intermingling of reactants and products. The enhanced mixing effectively wrinkles and increases the surface area of the flame front. The overall propagation rate is increased because chemical reactions occur across a larger area.

When the short chimneys were removed in existing TLUDs and Rocket stoves, several interesting things occurred. The draft was significantly reduced, assisting the flames to remain short. Insulating the inner surface of the stove body helped to deliver hot gases to the pot. However, it became harder to achieve Tier 5 (50%) thermal efficiencies.

The slow speed, turbulent flame conditions seem to dramatically reduce the emissions of PM2.5 in both stoves. Several TLUDs and several Rocket stoves without short chimneys have been built and tested under the emissions hood. A complete summary of results, with CAD drawings of the stoves, is being prepared.