Four Simple Changes = 56% Thermal Efficiency

We had a couple of days between jobs at the lab and decided to see if a simple Rocket stove manufactured in India, patterned after the BURN stove, could get better thermal efficiency. Low grade stainless steels, like 304, can’t withstand the hotter combustion chamber temperatures generated when insulated, so in the BURN stove room air is used to keep the steel cool enough to increase durability.

One of the key properties of any stainless steel alloy is its resistance to oxidation. High temperatures can compromise the oxidation resistance of steel alloys, leading them to become rusted and weakening their structural integrity.

As stated by AZO Materials, grade 304 stainless steel possesses “good oxidation resistance in intermittent service to 870°C and in continuous service to 925°C.” However, they warn that “continuous use of 304 in the 425-860°C range is not recommended if subsequent aqueous corrosion resistance is important.” In other words, you can expose grade 304 alloy steel to temperatures of up to 870°C for short periods of time without ill effect, and for extended periods of time in temperatures of up to 925°C. However, this can compromise the corrosion resistance of the metal, making it more susceptible to damage from exposure to moisture. (https://www.marlinwire.com/blog/what-is-the-temperature-range-for-304-stainless-steel-vs-316-vs-330)

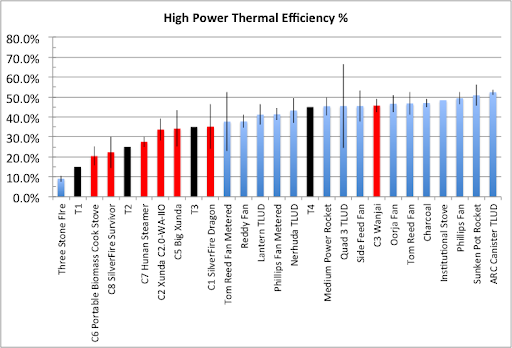

When the low mass, uninsulated BURN Rocket stove has (1) 6mm high pot supports, (2) a pot skirt that creates a 6mm channel gap around a family sized pot, and (3) a fire that creates hot, tall flames that transport 800°C to 1,000°C gases to the pot, the thermal efficiency has been measured at around 52%.

We lowered the pot supports in the simple Indian Rocket stove to (1) 6mm high and used a (2) 12cm high, 6mm channel gap pot skirt around a 25cm in diameter steel pot filled with 5 liters of water. Thinking that the simple Indian Rocket stove could use a 1,200°C thin walled refractory ceramic combustion chamber, (less than $1 from Shengzhou Stove Manufacturer), we (3) surrounded the combustion chamber with ceramic fiber insulation. (4) The fire was made from tiny sticks. Tiny sticks make hot, tall, dirty flames and use up the least amount of wood while making really hot gases. When burning tiny sticks, gas temperatures under the pot can be over 1,000°C. The 1,000°C gases heat water quickly and efficiently when 6mm channel gaps are used below and on the sides of the pot.

With these changes, the simple Indian Rocket stove scored an average of 56% thermal efficiency (3 tests to boil).

If (1) 6mm pot supports, (2) 6mm pot skirts, (3) insulation, and (4) tiny sticks making 1,000°C gases had been used in the 2014 DOE stove survey the average scores would have been a bit higher. One lesson is that channel gaps and types of fires can have a big effect on heat transfer efficiency.

Go for those 1,000°C gases flowing right next to surfaces for high thermal efficiency.

Add metering and mixing to 1,000°C gases with sufficient residence time and combustion efficiency is also improved.

Check out the heat transfer and combustion chapters in “Clean Burning Biomass Cookstoves, 2021” at www.aprovecho.org.

Leave a Reply

Want to join the discussion?Feel free to contribute!