What’s Cooking at Aprovecho

Aprovecho Visits Tanzania

In September, Jaden traveled to Tanzania to help set up a LEMS at the Bureau of Standards. Tanzania plans to set minimum standards for biomass stoves on the market, ensuring that more clean and efficient stoves are sold. She also visited Tango Energy, a stove manufacturer with whom Aprovecho has worked on stove design. She got to work on building knowledge with them and visited a project site to talk to households about their experience with improved stoves. We are excited to establish such great connections in Tanzania and hope to work with them in the future.

Increased Support for RTKCs

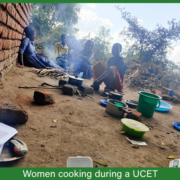

Regional Testing and Knowledge Centers (RTKCs) help us with testing, design, fieldwork and valuable knowledge of local cooking practices. Without them, we would not be able to make the global impact we do today. With our new grant funding, we will be supporting RTKCs in an effort to increase their testing and design capabilities, as well as building a better-connected community of testing centers and their researchers.

Test Results To Be Published

We performed a field study in Oregon on cordwood heating stoves, with the goal of understanding how people use these stoves so we can make cleaner-burning designs that still meet user needs. The results from that study are on their way to publication. This paper combines anthropology and engineering, using survey data, semi-structured interviews, and emissions data to find common usage patterns and identify high-emissions events. This work has helped immensely in our development of new cordwood heating stoves. The full paper has been accepted for publication in the Journal Energy Research and Social Science with the title: Considering the user: An integrated assessment of residential wood heating practices in the United States and implications for wood heater design. We will publish a link on our publications page, once it is available.