A Hospitable Chinese Environment for Improved Cookstoves

Information summarized via Google AI:

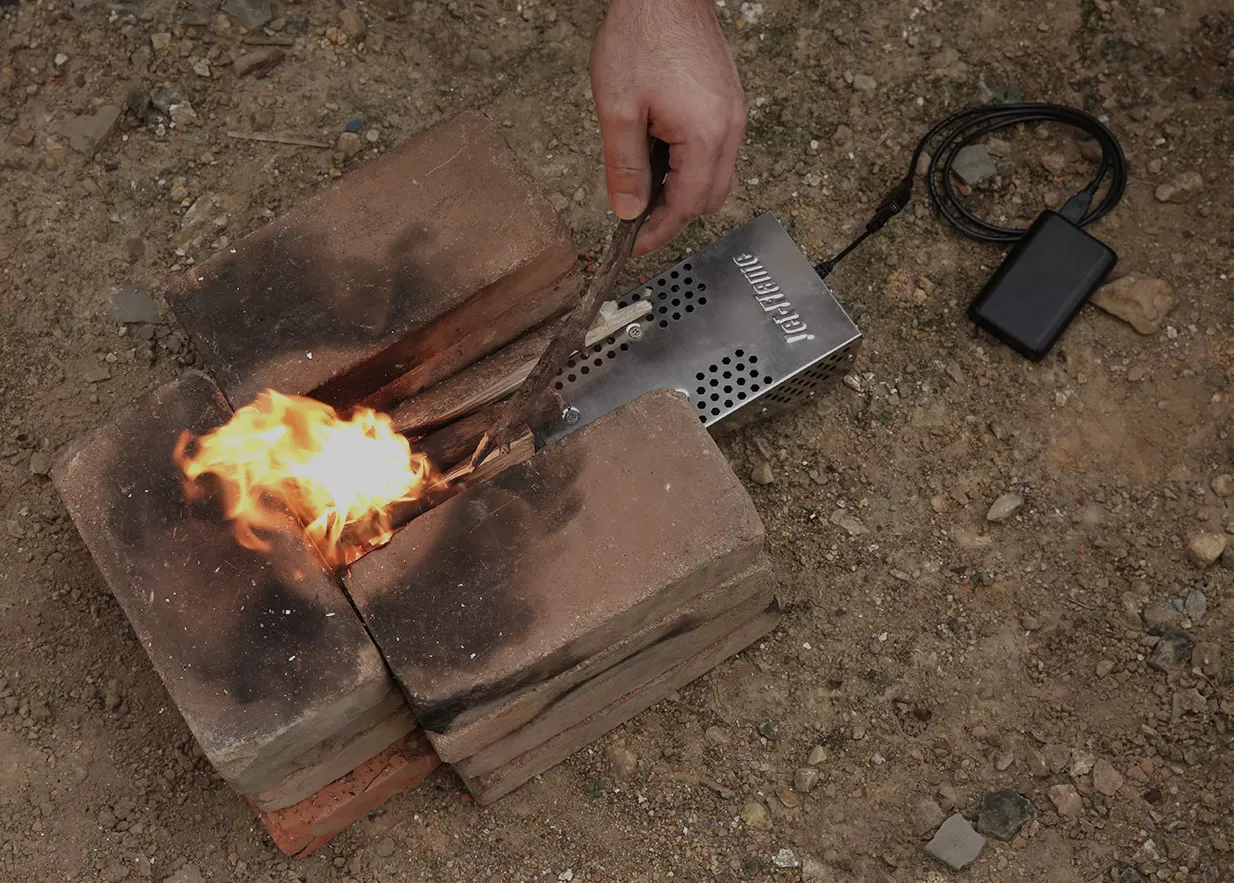

In 2026, the Chinese carbon market (CCER) is generally a more hospitable environment for cookstove projects—defined as traditional improved biomass stoves that lack advanced digital monitoring—compared to UN or Western voluntary markets.

While international markets now demand costly digital “metering” and stricter methodologies, the Chinese domestic market offers more flexibility for simpler projects.

- Protection from VCM Volatility: Traditional cookstove projects in Western markets are currently facing a “crisis of quality”. Large-scale studies in 2025 found that older projects likely over-credited by 900%, causing Western buyers to avoid them.

- The Chinese CCER market provides a sheltered environment where domestic compliance entities can still utilize these credits without the same level of global reputational risk.

- Methodological Lag: While Western markets are shifting to metered and measured standards (e.g., Gold Standard’s new digital tools), China’s revamped CCER scheme allows for traditional improved efficiency stoves that fit into its broader “dual control” carbon and energy policies.

- Price Floor: In 2026, “old-fashioned” credits in the global voluntary market have struggled to trade above $3.30/tCO2e. In contrast, CCERs are expected to maintain a higher floor ($10+) due to scarcity and mandatory offset needs within the Chinese ETS.

Tariffs

Recently many African countries removed tariffs on Chinese biomass cookstoves dramatically reducing cost to consumers. A widespread trend toward zero-rating clean cooking technologies has emerged to meet energy access goals. While China has eliminated tariffs on imports from 53 African nations, this does not automatically remove the duties African countries charge on Chinese-manufactured goods.

Recent Policy Changes (2026)

Several African nations have implemented specific exemptions for clean energy equipment:

: Under the 2026 Finance Act, the government has officially approved zero import duties on a wide range of clean cooking technologies, including improved biomass stoves and solar cookers.

: Effective in 2026, Cameroon has introduced customs exemptions for biofuel equipment, including industrial machinery used to produce pellets and eco-charcoal, to curb deforestation.

These nations were identified in early 2026 as having the greatest improvement in clean cooking policy coverage, frequently utilizing tax incentives and duty remissions to lower costs for consumers.

Nordica MacCarty

Nordica MacCarty