Aprovecho Announced as a Winner of the Wood Heater Design Challenge

The U.S. Department of Energy (DOE) Bioenergy Technologies Office (BETO), in collaboration with Brookhaven National Laboratory (BNL), Lawrence Berkeley National Laboratory (LBNL), and the Alliance for Green Heat, today announced the winning teams for the Wood Heater Design Challenge (WHDC).

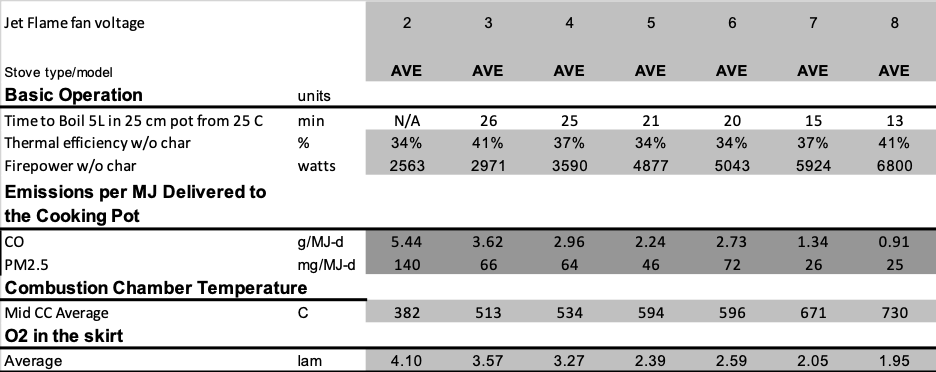

Aprovecho Research Center, from Cottage Grove, Oregon, came in second place and won $25,000 with a novel burn pot, airflow configuration, and sensor package for pellet heaters. Davidon Industries from Warwick, Rhode Island was awarded first place for their mechanically automated, combustion-air control technology for cordwood heaters. Kleiss Engineering from Cloverdale, Indiana, won the third-place prize with a smart wood stove heater.

“Embracing innovation allows us to challenge existing norms, push boundaries, and discover new solutions that can reshape the entire industry,” said Dr. Valerie Sarisky-Reed, Director of BETO. “Wood stove research is part of DOE’s overall strategy to develop affordable bioenergy technologies and convert our nation’s renewable resources into fuels, power, products and in this case, more efficient wood stoves for homeowners.”

Aprovecho, Davidon, and Kleiss were selected from nine teams competing at the Wood Heater Technology Slam in September 2022. Teams pitched new wood stove ideas to retailers, the public, and experts, who assessed which stoves were the most innovative, efficient, and offered the greatest market potential. The three finalist teams moved forward to the testing phase of the competition, which was held this past spring at BNL in Upton, New York.

Read the full press release on the DOE Website. Learn more about the BETO-funded Wood Heater Design Challenge.

Aprovecho Research Center

Aprovecho Research Center